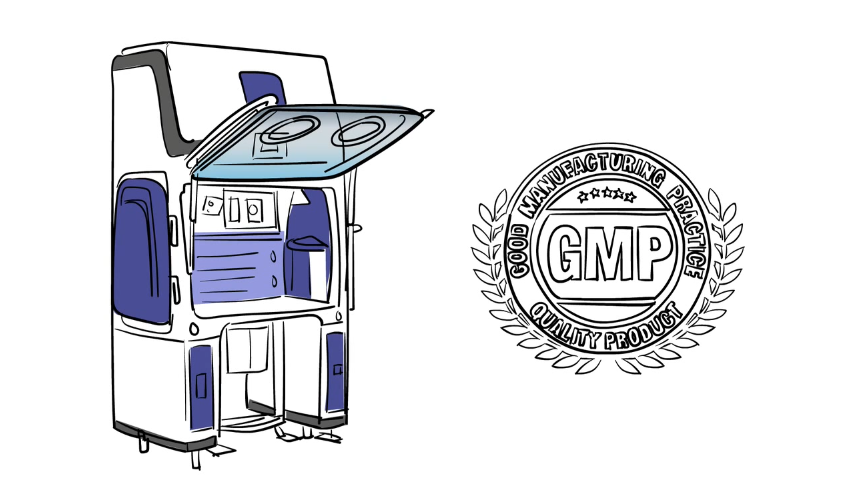

Bioquell Qube – Aseptic Isolator

UK Design & Made

Intelligent modular design for user flexibility

Rapid 20 minute bio-decontamination cycle

High level 6-log sporicidal bio-decontamination technology

Compliant with GMP Grade A - Annex 1

Revolutionary new range of fully integrated HPV solutions for sterility testing

Sterility testing is required during the sterilisation validation process, as well as for routine quality control and

detecting major contamination in a batch. The test environment should be as stringently controlled as an aseptic

processing environment. Sterility testing is an extremely difficult process that must be designed to eliminate

false positive results. False positive results are generally due to laboratory contamination from the testing

environment or technician error.

To meet the challenges of sterility testing, Bioquell has developed a revolutionary new fully integrated hydrogen

peroxide vapour (HPV) solution. The Bioquell QUBE offers a rapid sporicidal bio-decontamination process with

a high level validated 6-log reduction in bioburden.

This in-built bio-decontamination system has been designed to complement a fully fitted and validated sterility

test unit such as the market leading Millipore Steritest system.

Designed to act as a modular, barrier separation technology (‘closed system’), the Bioquell QUBE provides a

physical separation of operators to the sterility test process. The intelligent modular design principles give users

flexibility in selecting the most suitable configuration for their individual process. This allows users to build the

Bioquell QUBE system to their process requirements (e.g. a single module if space is at a premium, up to a full

3 workstation unit for high volume throughput).

The closed barrier technology also enables the user to apply automated HPV biological decontamination.

Within a single module, a rapid 20 minute bio-decontamination cycle* allows fast and efficient material

transfers. The in-built flexible gassing options also allow the user to bio-decontaminate multiple interfaced

Bioquell QUBE modules or separately bio-decontaminate test material and samples as part of a rapid gassing

transfer process. To help ensure users can maximise working area whilst maintaining aseptic conditions,

samples and waste removal can be made via a transfer hatch or rapid gassing port.